The ZF 6HP19 and 6HP21 are advanced 6-speed automatic transmissions known for their durability and versatility in various vehicle applications, including BMW, Audi, and other high-performance cars. Designed for smooth shifting and high torque capacity, these transmissions are popular among automotive enthusiasts and technicians. ZF Friedrichshafen AG, the manufacturer, provides comprehensive instruction manuals to ensure proper maintenance and repair. These resources are essential for technicians to understand the technical specifications, troubleshooting, and service procedures for optimal performance.

1.1 Overview of ZF 6HP19 and 6HP21 Automatic Transmissions

The ZF 6HP19 and 6HP21 are 6-speed automatic transmissions designed for high-performance vehicles, offering smooth shifting and reliability. These transmissions are widely used in BMW, Audi, and other premium vehicles due to their durability and versatility. Equipped with advanced torque converters and adaptive gear ratios, they cater to diverse driving conditions, from city commuting to high-speed performance. The 6HP19 and 6HP21 transmissions are known for their high torque capacity and fuel efficiency, making them popular among automotive enthusiasts and technicians. Both models share similar architectures but differ in specific applications and torque ratings, ensuring optimal performance across various vehicle configurations. The instruction manual provides detailed insights into their operation, maintenance, and repair.

1.2 Importance of Instruction Manuals for Transmission Maintenance

The ZF 6HP19 and 6HP21 instruction manual is essential for proper transmission maintenance, ensuring safety, efficiency, and longevity. It provides detailed procedures for disassembly, assembly, and troubleshooting, helping technicians avoid costly mistakes. The manual includes torque specifications, fluid requirements, and diagnostic guidelines, which are critical for maintaining optimal performance. Without it, improper repairs or maintenance could lead to transmission malfunction or reduced lifespan. Regularly updating knowledge with the manual ensures compliance with manufacturer standards, minimizing risks and enhancing reliability. By following its guidelines, technicians can perform precise repairs and maintain the transmission’s advanced features effectively, ensuring smooth operation in all driving conditions.

Structure of the ZF 6HP19/6HP21 Instruction Manual PDF

The manual is logically organized into sections, including technical specs, maintenance procedures, troubleshooting, and repair guidelines. It features a detailed table of contents and user-friendly layout.

2.1 Table of Contents in the Instruction Manual

The table of contents is a comprehensive guide that outlines all sections of the manual. It includes chapters on transmission specifications, maintenance schedules, troubleshooting, and repair procedures. Each section is clearly labeled, making it easy to locate specific information. The table of contents also highlights key areas such as fluid capacity, diagnostic steps, and safety precautions. This organized structure ensures that users can quickly navigate to the relevant parts of the document. The detailed indexing enhances usability, allowing technicians and enthusiasts to access critical data efficiently. This feature is essential for ensuring proper maintenance and repair of the ZF 6HP19 and 6HP21 transmissions.

2.2 Key Sections of the Manual

The ZF 6HP19 and 6HP21 instruction manual includes several key sections essential for transmission maintenance and repair. These sections cover technical specifications, maintenance schedules, and troubleshooting guides. The manual also provides detailed repair procedures, including step-by-step instructions for common issues. Additionally, it offers safety precautions to ensure safe handling of components. The key sections are designed to guide technicians through diagnostics, repairs, and routine maintenance. Each section is detailed to provide clear instructions, making the manual an invaluable resource for professionals and enthusiasts alike. The organized layout ensures that users can easily find the information they need to keep the transmission functioning optimally.

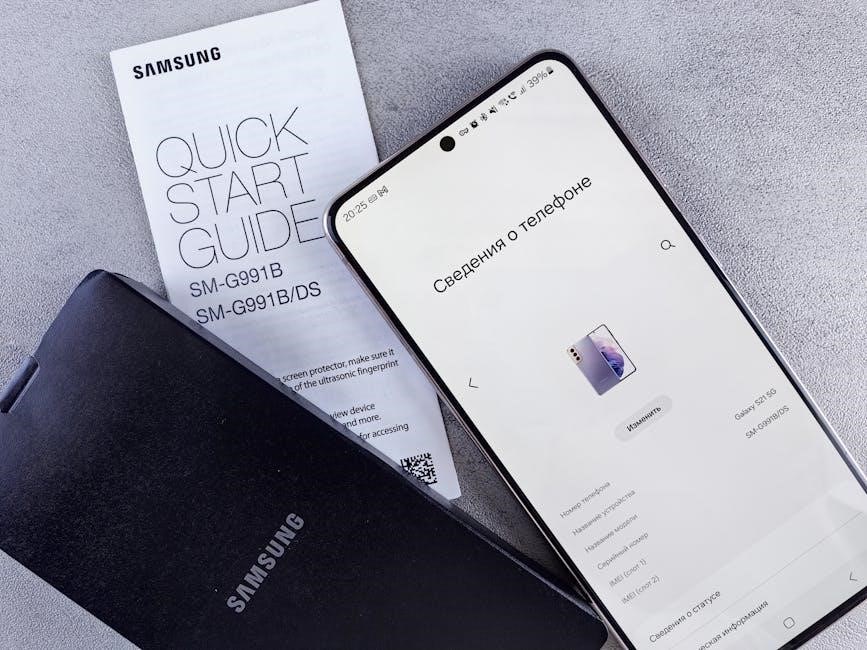

2;3 How to Navigate the PDF Document

Navigating the ZF 6HP19 and 6HP21 instruction manual PDF is straightforward due to its structured layout. The document features a detailed table of contents with bookmarks, allowing users to quickly jump to specific sections. Each chapter is divided into clear subsections, making it easy to locate information. The PDF also includes hyperlinks for cross-referencing related topics. Users can utilize the search function to find keywords or specific procedures. Additionally, the manual includes page numbering and clear headings to guide readers seamlessly through the document. These features ensure efficient navigation, enabling technicians to access critical information without delay.

Technical Specifications of ZF 6HP19 and 6HP21

ZF 6HP19 and 6HP21 transmissions feature 6 forward gears, torque capacities up to 600 Nm, and advanced mechatronic controls for smooth, efficient shifting in various vehicle applications.

3.1 ZF 6HP19 Transmission Specifications

The ZF 6HP19 transmission is a 6-speed automatic designed for longitudinal engine applications, offering a maximum torque capacity of up to 600 Nm. It features a compact, lightweight design and is suitable for both gasoline and diesel engines. The transmission incorporates ZF’s advanced mechatronic control system, ensuring precise gear shifting and optimal performance. Its modular architecture allows for easy integration into various vehicle platforms. The 6HP19 is known for its fuel efficiency, smooth operation, and durability. The instruction manual provides detailed specifications, including gear ratios, oil pressure ranges, and filter replacement intervals, essential for maintenance and repair procedures.

3.2 ZF 6HP21 Transmission Specifications

The ZF 6HP21 transmission is a high-performance 6-speed automatic, designed for longitudinal engine configurations, with a maximum torque capacity of up to 700 Nm. It is optimized for larger engines and vehicles, offering enhanced power delivery and fuel efficiency. The 6HP21 features ZF’s advanced mechatronic control system, ensuring precise and adaptive gear shifting. Its robust design makes it suitable for heavy-duty applications while maintaining smooth operation. The transmission’s specifications include optimized gear ratios, improved torque converter lock-up, and advanced clutch pack arrangements. The instruction manual provides detailed technical data, including oil requirements, filter specifications, and diagnostic parameters, essential for servicing and maintenance.

3.3 Differences Between 6HP19 and 6HP21 Models

The ZF 6HP19 and 6HP21 transmissions share a similar design but differ in key specifications. The 6HP21 is designed for higher torque applications, with a capacity of up to 700 Nm, compared to the 6HP19’s 600 Nm limit. The 6HP21 also features enhanced mechatronic control systems for improved shifting precision and adaptive capabilities. Gear ratio optimization differs slightly between the two models, with the 6HP21 offering better fuel efficiency in larger engine configurations. The instruction manual highlights these distinctions, ensuring technicians can tailor maintenance and repairs to the specific transmission type. Understanding these differences is crucial for proper servicing and performance optimization.

Maintenance and Service Procedures

Regular fluid checks, filter replacements, and software updates are essential for optimal performance. Adhere to ZF guidelines for torque specifications and genuine parts to ensure durability and efficiency.

4.1 Recommended Maintenance Schedule

The ZF 6HP19 and 6HP21 transmissions require regular maintenance to ensure optimal performance. The recommended schedule includes fluid changes every 30,000 to 60,000 miles, depending on driving conditions. Filter replacements should be performed annually or every 50,000 miles. Software updates for the mechatronic unit are necessary to maintain compatibility and functionality. Additionally, torque converter checks and solenoid inspections should be done every 100,000 miles. Always use genuine ZF parts and follow the manual’s guidelines for proper maintenance. Consulting the manual for specific intervals based on vehicle type and usage is crucial for longevity and reliability.

4.2 Fluid Capacity and Type for 6HP19/6HP21

The ZF 6HP19 and 6HP21 transmissions require a specific type of automatic transmission fluid (ATF) for optimal performance; The recommended fluid type is ZF 6HP24E or equivalent synthetic ATF. The total fluid capacity for a full drain and refill is approximately 9 liters for both models. However, during routine maintenance, such as a pan drop, only about 4-5 liters are replaced. Always consult the manual for precise measurements, as overfilling or underfilling can lead to performance issues. Using genuine ZF-approved fluids ensures compatibility and longevity of the transmission.

4.3 Proper Refilling Procedure After Maintenance

After draining the old fluid, thoroughly clean the pan and replace the filter. Refill the transmission with the recommended ZF 6HP24E synthetic ATF. Use a fluid pump or pour slowly to prevent air bubbles. Fill to the level specified in the manual, typically just below the “MAX” mark on the dipstick. Replace the filler plug and start the engine, allowing it to idle for a few minutes. Check for leaks around the pan and connections. Drive gently for a short distance to circulate the new fluid. Recheck the fluid level and top up if necessary. Always follow the manual for precise refill procedures to ensure proper transmission function.

Troubleshooting Common Issues

Common issues include slipping, rough shifting, or loss of power. Check for error codes, low fluid levels, or a faulty filter. Inspect for unusual noises or erratic behavior.

5.1 Common Problems in ZF 6HP19/6HP21 Transmissions

The ZF 6HP19 and 6HP21 transmissions are prone to issues like slipping between gears, harsh shifting, or loss of power. Common causes include worn clutch packs, faulty solenoids, or mechatronic unit malfunctions. Low transmission fluid levels or contamination can also lead to slipping or erratic behavior. Error codes such as P0750 (low/reverse solenoid circuit) or P1760 (transmission over-temp) often indicate specific faults. Additionally, torque converter shudder and overheating during heavy use are reported issues. Regular maintenance, such as fluid checks and filter replacements, can prevent many of these problems. Addressing these issues early is crucial to avoid costly repairs.

5.2 Diagnostic Steps for Identifying Faults

Diagnosing issues in ZF 6HP19/6HP21 transmissions involves a systematic approach. Start with a visual inspection for fluid leaks or contamination. Use a scan tool to retrieve error codes from the transmission control module (TCM). Tools like VCDS or ISTA/D are recommended for ZF-specific codes. Perform a test drive to monitor shifting patterns and slipping. Check the transmission pan for debris, which may indicate internal wear. Measure solenoid resistance to ensure proper electrical function. Verify fluid levels and condition, as low or degraded fluid can mimic mechanical faults. If issues persist, refer to the manual for specific troubleshooting charts and procedures.

5.3 Error Codes and Their Meanings

Understanding error codes is crucial for diagnosing ZF 6HP19/6HP21 transmission issues. Codes are stored in the transmission control module (TCM) and can be retrieved using a scan tool. Common codes include those related to solenoid performance, pressure control, and temperature faults. For example, code $2E91 indicates a pressure solenoid malfunction, while $2E92 points to a faulty pressure sensor. Referencing the ZF manual is essential for accurate interpretations. Each code corresponds to specific components or systems, guiding technicians to the root cause. Always cross-reference codes with symptoms and manual procedures for precise troubleshooting and repair.

Repair and Rebuilding Guidelines

This section provides detailed repair and rebuilding procedures for ZF 6HP19/6HP21 transmissions, including tools, techniques, and best practices for optimal performance and longevity.

6.1 General Repair Procedures for 6HP19/6HP21

General repair procedures for ZF 6HP19/6HP21 transmissions involve thorough preparation, specialized tools, and adherence to manufacturer guidelines. Begin by disconnecting the battery and draining the transmission fluid. Next, remove the transmission pan and filter to inspect for debris or contamination. Identify and address any leaks or worn seals. Replace faulty solenoids, sensors, or clutch packs as needed. Always refer to the instruction manual for torque specifications and reassembly steps. Proper alignment of the valve body and mechatronic unit is critical. Use approved transmission fluid and ensure all electrical connections are secure. Testing the transmission under controlled conditions is essential before returning the vehicle to service.

6.2 Step-by-Step Transmission Rebuilding Process

The rebuilding process for ZF 6HP19/6HP21 transmissions requires meticulous attention to detail. Begin by disassembling the transmission, removing the bellhousing, and separating the main case from the valve body. Inspect all components, including clutch packs, seals, and bearings, for wear or damage. Replace any damaged parts with genuine ZF spare parts. Reassemble the transmission by installing the clutch packs, seals, and bearings, ensuring proper alignment. Reattach the valve body and mechatronic unit, following torque specifications from the manual. Finally, refill the transmission with the recommended fluid and perform a leak test. Always refer to the instruction manual for precise reassembly steps and testing procedures.

6;3 Replacement of Key Components (Valve Body, Mechatronic Unit)

Replacing the valve body and mechatronic unit in ZF 6HP19/6HP21 transmissions requires precision. Start by removing the transmission pan and filtering the old fluid for reuse. Disconnect the electrical connectors linked to the mechatronic unit and valve body. Remove the bolts securing the valve body and carefully lift it out. For the mechatronic unit, disconnect the electrical connector and remove the mounting bolts. Install the new components in the reverse order, ensuring proper alignment and torque specifications. Reconnect all electrical connectors and refill the transmission with the recommended fluid. Finally, perform a test drive to ensure smooth operation and verify no error codes are present. Always use genuine ZF parts for reliability.

Spare Parts and Accessories

The ZF 6HP19/6HP21 instruction manual provides a detailed spare parts catalog, including gaskets, seals, and selective shims. It also lists torque converters, solenoid kits, and recommended tools for repairs. Genuine ZF parts ensure reliability and compatibility. Always refer to the manual for proper installation and torque specifications to maintain transmission performance and longevity.

7.1 Spare Parts Catalog for 6HP19/6HP21

The ZF 6HP19/6HP21 instruction manual includes a comprehensive spare parts catalog, detailing every component needed for maintenance and repair. It lists part numbers, descriptions, and quantities for items like gaskets, seals, selective shims, and torque converter components. The catalog is organized by transmission sub-assemblies, making it easy to locate specific parts. Regular updates ensure the catalog reflects the latest technical specifications. Users can cross-reference parts using diagrams and tables provided in the manual. This section is essential for technicians to source genuine ZF parts, ensuring compatibility and performance. Always consult this catalog before ordering parts to avoid mismatches and ensure proper transmission function.

7.2 Selective Shims and Snap Rings Information

The ZF 6HP19/6HP21 manual provides detailed information on selective shims and snap rings, critical for precise transmission assembly. These components ensure proper clearance and alignment of internal parts. The manual lists specifications, part numbers, and installation guidelines for shims and snap rings. It explains how to measure and select the correct shim size using torque and clearance charts. Proper installation techniques are highlighted to prevent damage or misalignment. The section also covers common mistakes to avoid, such as overtightening snap rings. This information is vital for technicians to maintain transmission performance and durability during repairs or rebuilds, ensuring accurate reassembly every time.

7.3 Recommended Tools for Transmission Repair

The ZF 6HP19/6HP21 manual outlines essential tools for transmission repair, ensuring accurate and efficient servicing. These include a socket set, torque wrench, and specialized tools like a transmission pan gasket tool. A dial indicator is recommended for precise measurements, while a seal installer prevents damage during reassembly. The manual also lists tools for mechatronic unit repairs, such as a CAN bus interface. Using ZF-approved tools or equivalents is crucial to avoid component damage; Proper tool usage is emphasized to ensure safety and effectiveness during repairs. This section helps technicians prepare adequately, reducing downtime and potential errors during transmission maintenance or rebuilds.

Safety Precautions and Best Practices

Always wear protective gear like gloves and safety glasses when handling transmission components. Ensure proper lifting techniques to prevent injury. Follow manufacturer guidelines strictly to avoid accidents and ensure reliable repairs.

8.1 Safety Guidelines for Handling Transmission Components

When working with ZF 6HP19/6HP21 transmissions, always wear protective gear such as gloves and safety glasses to prevent injuries. Use a hoist or jack stands to securely lift and support the vehicle, ensuring stability before starting repairs. Avoid handling hot transmission components, as they can cause burns. Properly secure the vehicle on level ground to prevent accidental movement. Be cautious of sharp edges on transmission cases and components, which can cause cuts. Keep the workspace clean and well-lit to minimize hazards. Refer to the ZF instruction manual for specific safety recommendations. Always follow proper procedures to avoid damage to components and ensure personal safety.

8.2 Use of Proper Torque Specifications

Adhering to correct torque specifications is crucial when servicing ZF 6HP19/6HP21 transmissions to ensure reliability and prevent damage. Always reference the official ZF instruction manual for precise torque values, as they vary by component. Improper torque can lead to leaks, stripped threads, or premature part failure. For instance, bolts on the valve body and transmission pan require specific torque to maintain sealing integrity. Use a calibrated torque wrench to apply the exact specifications. Double-check torque values before reassembling critical components. Proper torque ensures optimal performance, longevity, and safety of the transmission. Never guess torque settings—always rely on the manual for accuracy.

8.3 Importance of Following Manufacturer Instructions

Following ZF manufacturer instructions is essential for maintaining the integrity and performance of 6HP19/6HP21 transmissions; Deviating from guidelines can lead to system malfunctions, reduced lifespan, or even safety hazards. The manual provides precise engineering standards for maintenance, repairs, and diagnostics. Ignoring these instructions can void warranties or result in costly repairs. Always prioritize the manufacturer’s recommendations for fluid types, maintenance schedules, and diagnostic procedures. This ensures compliance with design specifications and optimal transmission functionality. Proper adherence also minimizes the risk of errors during repairs. Refer to the official ZF manual as the primary source for all transmission-related tasks to guarantee reliability and safety.

Resources and Support

ZF provides extensive resources, including official documentation, online forums, and professional training programs, to ensure optimal support for maintenance and repair of 6HP19/6HP21 transmissions.

9.1 Official ZF Aftermarket Support and Documentation

ZF provides comprehensive aftermarket support and documentation for 6HP19 and 6HP21 transmissions, ensuring professionals have access to accurate and detailed resources. The official instruction manual PDF includes technical specifications, maintenance procedures, and repair guidelines, all designed to help users understand and service these transmissions effectively. ZF’s dedicated website offers downloadable resources, service bulletins, and technical updates, ensuring technicians stay informed about the latest advancements. Additionally, ZF’s customer support team is available to assist with inquiries, providing expert guidance for complex repair scenarios. This robust support system underscores ZF’s commitment to maintaining the performance and longevity of its transmissions.

9.2 Online Forums and Communities for Transmission Repair

Online forums and communities are invaluable resources for technicians working on ZF 6HP19 and 6HP21 transmissions. Platforms like Reddit, Transmission Rebuild Forums, and specialized Facebook groups offer spaces to share knowledge, ask questions, and access real-world insights. Many forums host discussions on troubleshooting, repair tips, and experiences with the instruction manual PDF. These communities often include DIY enthusiasts and professional technicians who provide advice on optimizing maintenance and repair processes. Additionally, some forums share links to supplementary guides, diagnostic tools, and aftermarket support resources. Engaging with these communities can enhance understanding and problem-solving skills for both novice and experienced technicians working on ZF transmissions.

9.3 Professional Training Programs for Transmission Technicians

Professional training programs are essential for mastering the repair and maintenance of ZF 6HP19 and 6HP21 transmissions. ZF Friedrichshafen AG offers certified training courses through its aftermarket divisions, providing in-depth knowledge of transmission mechanics, diagnostics, and repair. Additionally, technical schools and specialized automotive institutes offer programs tailored to automatic transmissions. These courses often include hands-on workshops and theoretical lessons, covering topics like mechatronic systems and valve body calibration. Many programs also reference the instruction manual PDF, ensuring technicians understand proper procedures. Such training equips technicians with the skills to handle complex repairs and stay updated on the latest advancements in transmission technology.

The ZF 6HP19/6HP21 instruction manual PDF is a comprehensive guide for transmission maintenance, repair, and troubleshooting. Following its guidelines ensures optimal performance, reliability, and longevity of the unit.

10.1 Summary of Key Points in the Instruction Manual

The ZF 6HP19 and 6HP21 instruction manual provides detailed guidance for transmission maintenance, repair, and troubleshooting. It covers technical specifications, maintenance schedules, fluid requirements, and diagnostic procedures. The manual emphasizes proper safety protocols and the use of genuine spare parts. Key sections include step-by-step repair processes, torque specifications, and error code interpretations. Adherence to the manual ensures optimal transmission performance and longevity. Professionals and DIYers alike can rely on this resource for accurate and comprehensive instructions tailored to ZF transmissions. By following the guidelines, users can effectively maintain, diagnose, and repair the 6HP19 and 6HP21 models, maximizing their reliability and service life.

10.2 Final Tips for Effective Transmission Maintenance

Consistent maintenance is crucial for extending the life of ZF 6HP19 and 6HP21 transmissions. Always refer to the instruction manual for specific guidelines. Regular fluid checks and timely replacements prevent internal damage. Avoid extreme temperatures and sudden acceleration, which can strain the system. Ensure proper torque specifications during repairs to maintain component integrity. Use genuine spare parts to guarantee compatibility and performance. Keep a maintenance log to track service history. Address error codes promptly to prevent minor issues from escalating. Finally, consider professional assistance for complex repairs to ensure reliability and safety. By following these tips, you can optimize transmission performance and minimize long-term costs.